To avoid confusion;

The topic is "Counter Flow Sluice". This should not be confused with ALL other forms of sluices, old and new and the many semantics that have been the subject of debate over the past thirty years.

At the introduction, the concept of a multi-level sluice was brought forward. The Top level provides a high velocity stream where oversize is transported down and out of the sluice. The top level is punched plate. Punched plate provides a boundary between two velocities. High velocity on top and low velocity underneath. It also provides classification of sediments. In my case, the holes are 1/4 inch. Looking at the top of the sluice, the entire top level is 1/4 inch punched plate.

The sluice is set at almost 30 degree slope.

The obvious concern with an extremely high angle is the velocity of the water flow. This is where the "Counter Flow" comes into place. In order to slow the flow, a mechanism has to be in place to resist or impede the flow.

When GOLD goes from a high velocity stream to a slower stream, it tends to settle. Sediments having less "mass" remain in the stream and exit the sluice. With the appropriate mechanism in place, conditions can be made most favorable for small GOLD to remain in a sluice.

Expanded metal;

Expanded metal comes in two forms, flat expanded metal and raised expanded metal. Raised expanded metal has ridges that are slightly elevated and angled for use in walk ways in industrial areas. Typical application of raised expanded metal in a sluice box is to orient the raised edges down slope. Down slope orientation of the raised expanded metal provides an upward ramp with a sudden drop similar to a riffle! Thousands and thousands of riffles that catch GOLD.

In a "Counter Flow" application, the direction of the raised expanded metal is REVERSED!

That's right! Because the objective is to SLOW the flow, the reversed raised expanded metal creates thousands and thousands of miniature "dams". The dams also provide "pockets" for GOLD to settle!

From my research on the subject, this represents the FIRST published record of this method of COUNTER FLOW applied in a Sluice box used for concentration of placer GOLD.

The concept is important because it allows recovery of GOLD in a sluice that has an extremely high angle. The raised expanded metal is UNDER the punched plate! Top side of the punched plate is high velocity as is desired to push over-sized material out of the sluice box. Under the punched plate, the reverse raised expanded metal has the benefit of slowing the flow and providing thousands of pockets to catch GOLD.

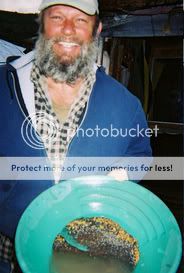

I am demonstrating the Counter Flow Sluice in my mining operation this week at Ophir. It represents a "working model" that can form a basis for further experimentation with the Counter Flow concept.

Stick around and find out how well it works!

- Geowizard